The world of gear pumps is evolving at a pace faster than most industries can keep up with. These essential components, known for their efficiency and robustness, are vital in a range of sectors, from automotive to chemical processing. But what’s next for gear pumps? How are trends and innovations shaping their future? In this article, we’ll explore the latest advancements in gear pump technology, what they mean for businesses, and why staying informed is crucial for those reliant on these powerful tools.

Understanding Gear Pumps

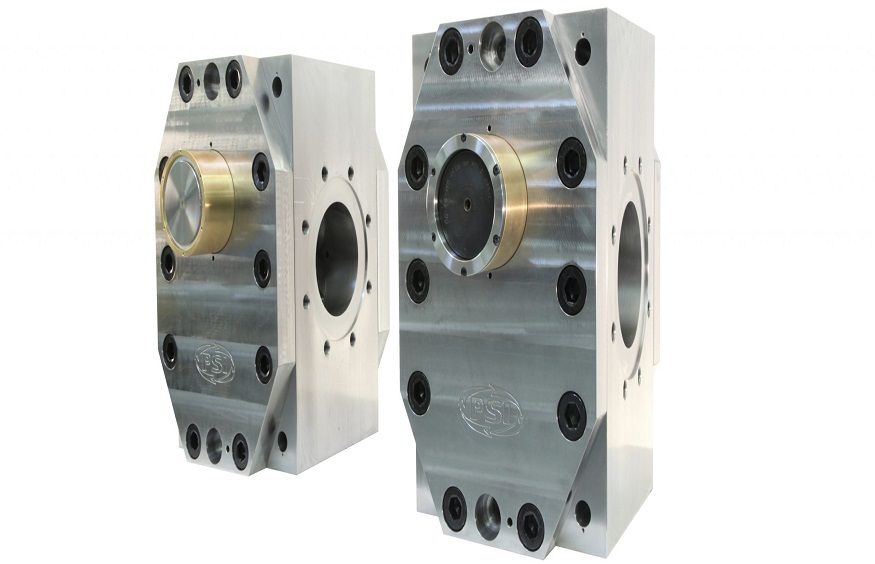

Gear pumps are a type of positive displacement pump, meaning they move a precise amount of fluid in each cycle. They are incredibly efficient at handling a variety of fluids, including those with high viscosity. Their design consists of two or more gears that work together to displace the fluid. The simplicity and reliability of gear type pumps make them a go-to choice for many industrial applications.

Their ability to handle high-pressure tasks with precision has made them indispensable in fields like agriculture, automotive, and chemical manufacturing. But as industries evolve, the demands placed on these pumps are changing. In response, manufacturers are innovating at an unprecedented rate, ensuring that gear pumps remain at the forefront of pumping technology.

Innovations in High Pressure Gear Pumps

One of the most exciting areas of development is the rise of the high pressure gear pump. These pumps are designed to operate under extreme conditions, effectively handling increased pressure without compromising performance. Innovations in materials and design are allowing these pumps to deliver higher efficiency and longer lifespans.

Manufacturers are experimenting with advanced alloys and composite materials to enhance durability and reduce wear. The result is gear pumps that can function effectively in harsh environments, such as deep-sea oil rigs or high-temperature industrial processes. This trend towards more robust and resilient gear pumps is set to continue, providing businesses with reliable, long-lasting solutions.

Another significant innovation is the integration of smart technology. By equipping gear pumps with sensors and IoT capabilities, industries can monitor performance in real-time. This advancement allows for predictive maintenance, reducing downtime, and optimizing operational efficiency. In the future, we can expect to see even more sophisticated technology embedded within these pumps, further enhancing their functionality and reliability.

Trends Influencing Gear Pump Technology

The ongoing trend towards sustainability is having a profound impact on gear pump technology. Industries are increasingly seeking solutions that minimize environmental impact, and gear pumps are no exception. Efforts are being made to improve the energy efficiency of these pumps, reducing their carbon footprint and operational costs.

Manufacturers are focusing on minimizing leakage and maximizing efficiency. By refining the precision of gear tooth design and improving sealing technologies, gear pumps are becoming more efficient than ever before. This trend is not only beneficial for the environment but also for businesses looking to cut costs and improve performance.

Additionally, customization is becoming more prevalent. Businesses are demanding pumps tailored to their specific needs, and manufacturers are responding with bespoke solutions. This shift towards customization ensures that gear pumps can meet the unique requirements of different industries, from food processing to pharmaceuticals.

Challenges Facing Gear Pump Advancements

While the future of gear pumps looks promising, several challenges must be addressed. One of the primary concerns is the cost of innovation. Developing new materials and technologies can be expensive, and manufacturers must balance the cost with the benefits provided to consumers. It’s a delicate balance, as businesses demand both cutting-edge technology and cost-effective solutions.

Another challenge is the need for skilled labor. As gear pumps become more sophisticated, the demand for skilled technicians to maintain and operate them increases. Companies must invest in training their workforce to ensure they can fully leverage the benefits of the latest technological advancements.

Regulatory requirements are also evolving. Industries are subject to stringent environmental and safety standards, which gear pumps must adhere to. Manufacturers must stay ahead of these regulations, ensuring their products are compliant without sacrificing performance or efficiency.

The Future of Gear Type Pumps

Looking ahead, the future of gear type pumps is filled with potential. With continued advancements in materials, technology, and design, these pumps will become even more integral to various industries. Their ability to adapt to changing demands ensures they will remain a vital component in numerous applications.

The shift towards digitalization will drive innovation. By incorporating more sophisticated monitoring and control systems, gear pumps will become smarter and more efficient. This evolution will open up new possibilities for automation and process optimization, further cementing their place in modern industry.

Sustainability will remain a key focus. Manufacturers will continue to seek ways to reduce the environmental impact of gear pumps. By enhancing energy efficiency and minimizing waste, they will help industries meet their sustainability goals, contributing to a greener future.

Gear pumps have stood the test of time as reliable, efficient, and versatile solutions for a variety of industries. The future promises even greater advancements, with innovations that will enhance their performance and adaptability. By staying informed about these trends, businesses can harness the full potential of gear pumps, driving efficiency and sustainability in their operations.

For those in industries reliant on gear pumps, now is the time to consider how these innovations can benefit your business. Whether it’s through improved performance, reduced costs, or enhanced sustainability, the future of gear pumps holds immense promise. Keep an eye on these trends and innovations, and don’t hesitate to explore how they can transform your operations for the better.